Axe Sheath pt 1

At the end of this month is a very important date. The Teacher’s wedding. Because of certain circumstances I will be one of the groomsmen (which I’m quite happy about). The theme is sort of a fantasy/medieval styled thing and so many of the groomsmen will be wearing a sword or other weapon as well.

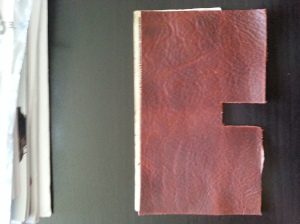

Personally, I don’t have any medieval style swords, but I do have a neat looking axe that I purchased at the Michigan Renaissance Festival.

(Forgive the poor quality picture, I’ll replace it later)

It’s beautiful and would be perfect! Except that it’s sharp and the frog I have places it uncomfortably close (and the bottom part (not pictured) scraped up my ankle pretty bad). So, Solution? Make a sheath of course! I grabbed some tools and some leather off of amazon and planned it out with my brother!

After the leather finally arrived I still wasn’t quite sure but now I’m in something of a time crunch so i need to get everything cut out so I can ship the axe down to The Teacher in time for the wedding! My brother recently had his own wedding a few days ago so he won’t be able to help for this part of it however he did let me know I could use some of his old sewing supplies. So I dug into that and gathered all the tools I figured I could use!

Here are all of the tools I’m planning to use, some mine some his. The ruler, pencil, awl, rotary cutter, stitching spacer, and needles are mine. Whereas the L-Square, big scissors, and soapstone are my bro’s. I haven’t used all of these tools yet, and I may add more but this is the list right now haha.

So I measured out the designs and started by cutting out a square that was around half an inch bigger than what I needed. Then I traced the shape of the blade onto the leather with the soapstone. Once I had that I guestimated about an additional centimeter and drew freehanded the cutting lines. I checked it on the axe and started cutting!

Curves with the rotary cutter aren’t as easy as I’d hoped, but they’re a lot easier than using a box cutter like I did when I made my wallet. It didn’t seem to stretch out the leather at all and with a careful hand I ended up with my first piece ready!

As you can see, I also added an additional part for the axe to cut into so it won’t cut through my stitches later on!

I took this cut out, flipped it over and traced it to get the second piece! Which was a little tougher to cut out, and i’m pretty sure it’s nto completely even as of yet but it was starting to get dark so I wanted to get another rough part done before I tried to do any fine work. It’s much easier to see things under natural light than the kitchen light so after I finished the first part for the second bit of my axe I called it a night.

So next time I just have to fine tune some of the parts and make the final cutout for the second bit! I still have some work to do with making a cover for the bottom weight but I feel pretty accomplished! After that I just have to figure out if I’m going to stitch it up with fake sinew, or waxed thread!

I’ve never used either so i’m not sure what to pick…

So if you’ve got any insights please comment below! Have you ever had a project to make something like this? Medieval styling or otherwise? Feel free to post any other questions or comments, I’d love to hear from you!